Discover superior performance and durability with our specialized tape solutions, designed to meet the toughest industry demands.

TITUS® Industrial Group delivers cutting-edge tapes and coatings designed to solve tough problems across commercial and industrial settings. From sealing concrete and repairing asphalt cracks to reinforcing vapor barriers and geomembranes, these specialized products are built for performance and reliability. The lineup features everything from primer-free pipe wraps to durable epoxy coatings and easy-to-remove petroleum wax modules, giving you versatile tools to handle complex jobs with confidence. If you’re unsure which product is right for your project, our team is ready to guide you to the ideal solution—get in touch today!

In demanding industrial environments, traditional tapes often fall short. They break down under extreme temperatures, lose adhesion when exposed to moisture, and fail to bond properly to uneven or contaminated surfaces. Construction crews face delays when products require complicated primers or don’t conform to irregular joints. In infrastructure applications, routine repairs become recurring headaches when materials degrade faster than expected. Across industries, the constant battle is the same—unreliable tape products that can’t keep up with the realities of fieldwork.

TITUS® industrial tapes are built to outperform where standard products fail. Designed for extreme durability, they maintain strong adhesion through heat, moisture, and surface irregularities without the need for primers. Whether applied to rough concrete, metal, or geomembranes, these tapes conform easily and bond reliably, even in less-than-ideal conditions. Fast application reduces downtime on job sites, while long-term performance minimizes repeat repairs. In environments where failure isn’t an option, TITUS delivers the dependable performance professionals can trust.

In the construction and infrastructure world, durability and reliability are non-negotiable. TITUS® tape solutions are engineered to perform in harsh conditions where standard materials fall short. From sealing foundation membranes to protecting critical joints and surfaces, our advanced tapes support long-term structural integrity across large-scale building projects and civil infrastructure. Designed for easy application and long-lasting adhesion, these products help crews stay efficient without compromising performance.

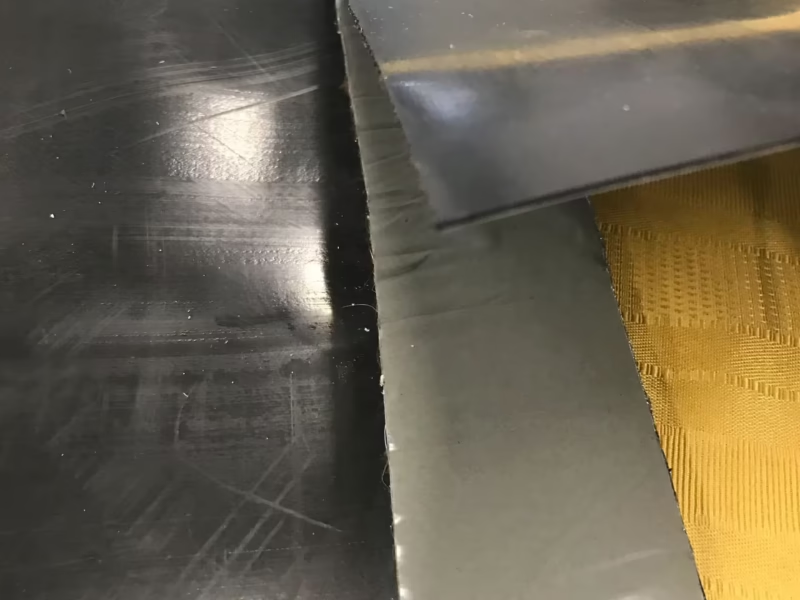

Engineered for demanding environments, Tapecoat® G-25 creates a strong, instant bond to a wide range of materials including polyethylene, polypropylene, PVC, Hypalon, EPDM, and rubber. Its aggressive synthetic adhesive forms a reliable air, vapor, and watertight seal across both geomembranes and geotextiles. Designed for use above or below grade, it offers versatile protection where containment and durability are critical.

Built for the toughest applications, Tapecoat® H-35 and H-50 offer the same powerful adhesive and UV-resistant backing as the G-25—now with added strength. A thicker backing delivers enhanced adhesion on rough surfaces, greater puncture and abrasion resistance, and the added benefit of an integrated primer. These heavy-duty tapes are ideal for demanding conditions where extra durability is a must.

Tapecoat® M-50 is a below-grade reconditioning tape built for strength and stability. Its synthetic rubber adhesive with an integrated primer ensures lasting adhesion, while the tough woven polypropylene backing resists stretching, making it ideal for maintaining integrity under soil pressure. This design eliminates common issues like soil stress and pipewrap bagging, offering reliable performance in underground environments.

Tapecoat® M-860 is a pre-formed, cold-applied, self-adhering material designed for high-performance sealing. Made with specially formulated elastomeric resins bonded to a woven polymer, it offers exceptional puncture resistance while remaining impermeable to water and salt. This tape is perfect for sealing cracks and joints in pavement or concrete, providing a long-lasting, durable solution for tough surfaces.

Tapecoat® Moldable Sealant is a flexible, watertight adhesive sealant tape designed for a variety of sealing and seaming applications. It bonds effectively to materials such as polypropylene, polyethylene, Hypalon, PVC, EPDM, rubber, most geotextiles, GCLs, aluminum, steel, fiberglass, and concrete. Ideal for forming custom seals, this product must be kept UV protected to maintain its performance and durability.

Tapecoat® tapes are designed to bond securely to a wide variety of surfaces, making them versatile for many applications. Whether it’s geomembranes, geotextiles, concrete, PVC, EPDM, rubber, or metals, our tapes deliver strong adhesion to both smooth and rough surfaces. This makes them ideal for use in construction, infrastructure, and industrial applications where surface materials vary.

The adhesive properties of Tapecoat® tapes are engineered to ensure reliable performance in demanding environments, even when surfaces are irregular or exposed to harsh conditions. From wet environments to extreme temperatures, Tapecoat® tapes maintain their bond, reducing the need for frequent repairs and ensuring long-lasting protection across various materials.

Tapecoat® tapes are built to withstand extreme weather conditions, including high heat, moisture, and UV exposure. Designed for both above and below-grade applications, these tapes maintain their adhesive properties even in the most challenging environments. Whether in freezing temperatures or scorching heat, Tapecoat® tapes offer reliable, durable sealing that helps to prevent leaks and structural damage.

The UV-resistant backing and aggressive adhesive ensure that the tapes perform consistently over time, offering protection against environmental wear. This durability means less maintenance and fewer repairs, saving time and money while enhancing the longevity of your projects, no matter the weather.

Applying Tapecoat® tapes is straightforward and designed to minimize downtime during installation. The tapes are self-adhesive, meaning they don’t require additional primers or complex preparation steps in most cases. Simply peel off the backing, press the tape into place, and it will bond immediately, providing a strong, long-lasting seal. This ease of application helps speed up project timelines and reduces labor costs.

For surfaces that may require additional preparation, such as cleaning or slight roughening, Tapecoat® tapes can still be easily applied with minimal effort. This versatility ensures that even in tougher conditions, you can count on a quick, efficient installation that delivers lasting results.

Looking for durable, high-performance tapes for your next project? Reach out today and let us help you find the ideal solution for your industry.